What is PET and Why Is It Used in Bottle Manufacturing?

Take a quick look around you: that water bottle on your desk, the juice in your fridge, or the cooking oil in your kitchen cabinet. Ever stopped to think about what they’re all made of?

You probably use bottles like these every single day without giving them a second thought. They’re light, clear, and sturdy… but what’s the secret behind them?

That secret is PET, the backbone of modern packaging.

Now, don’t worry, we’re not diving into a chemistry lecture! PET might sound like something straight out of a science lab, but it’s actually one of the most common (and fascinating) materials you use daily, and if you’re a business owner, it’s probably the very material protecting your products right now.

In this blog, we’ll uncover what PET (Polyethylene Terephthalate) really is, why it’s used in bottle manufacturing, and how it has helped countless brands from beverage companies to household product manufacturers—deliver freshness, safety, and quality in every single bottle.

Spoiler alert: by the end, you’ll see why switching to PET plastic bottles could be one of the smartest moves for your business.

So, What Exactly Is PET?

PET stands for Polyethylene Terephthalate (yes, it’s a mouthful, that’s why everyone just calls it PET!). It’s a type of plastic that’s lightweight, strong, and safe for packaging food and beverages.

You’ll usually find PET being used to make:

- Juice bottles

- Cooking oil bottles

- Water plastic bottles with caps

- Sauce and ketchup containers

- Edible product jars

- And even packaging for cosmetics and cleaning products.

What makes PET stand out is that it’s clear like glass, but much lighter and far less likely to break. Plus, it’s 100% recyclable, which means after you’ve finished your drink, the bottle can be turned into something new instead of going to waste.

Pretty cool, right?

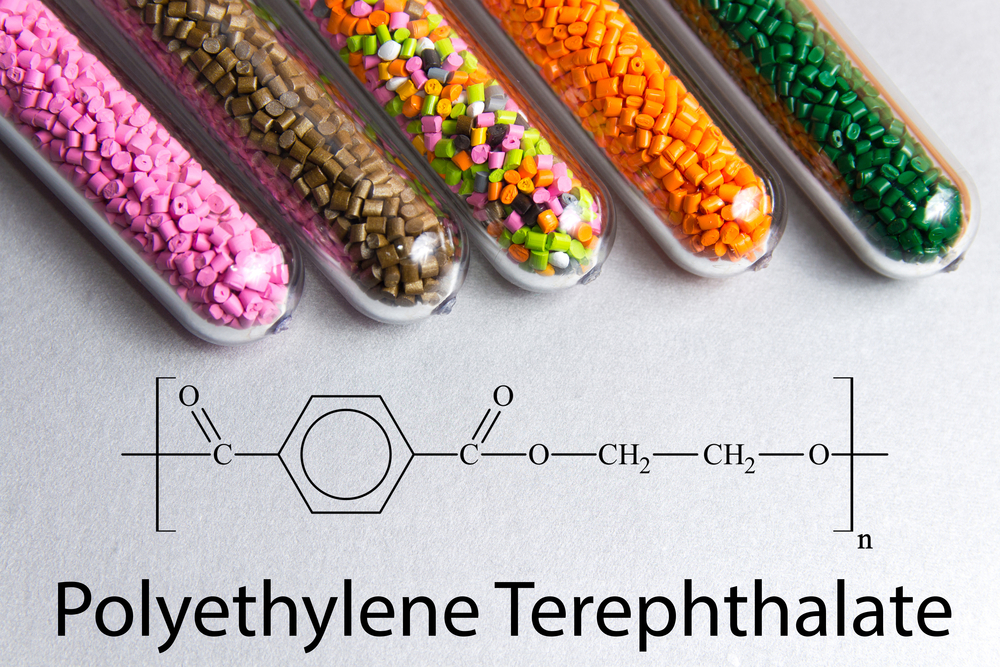

How PET is Made

Without getting too technical, PET is made from a reaction between two basic ingredients: purified terephthalic acid (PTA) and monoethylene glycol (MEG). When these two combine under heat, they form a long chain of molecules known as polymer resin.

This resin is then melted, molded, and shaped into things like preforms (the small test-tube-like shapes you might have seen before bottles are blown). These preforms are later heated and stretched into the familiar bottle shapes you see on shelves.

It’s like magic, but with science!

Why Is PET So Popular in Bottle Manufacturing?

Now that you know what PET is, let’s talk about why it’s so widely used in making bottles. In the world of PET bottle manufacturing, there are plenty of good reasons, and once you know them, you’ll understand why it’s the world’s favorite packaging material.

1. Lightweight but Strong

Imagine carrying a dozen glass bottles, heavy, right? PET plastic bottles, on the other hand, are super lightweight yet strong enough to hold water, juices, oils, or even carbonated drinks.

That’s why companies love using PET. It reduces shipping costs, makes handling easier, and keeps products protected during transport.

For customers, it means bottles that are easy to carry and safe to use, especially when you’re on the go.

2. Crystal Clear Appearance

People eat and drink with their eyes first! PET bottles have a glassy, transparent look that makes beverages and liquids appear clean, fresh, and premium.

Be it the golden color of cooking oil or the bright orange of mango juice, PET bottles show off the product beautifully while keeping it safe inside.

3. Safe for Food and Beverages

PET is a food-safe material, meaning it doesn’t react with the liquids it holds. It doesn’t give off any smell, doesn’t change the taste, and doesn’t contaminate what’s inside.

That’s a big reason why it’s trusted for packaging drinking water, milk, juices, and edible oils. Every PET bottle goes through strict quality control and safety checks before it’s ready for use.

4. Excellent Barrier Properties

One of PET’s superpowers is its ability to protect contents from outside elements. It acts as a strong barrier against moisture, oxygen, and bacteria.

This means beverages stay fresher for longer, and oils or sauces don’t go rancid quickly. For brands, that means longer shelf life and fewer quality complaints.

5. Cost-Effective Production

Compared to glass or metal packaging, PET bottles are much cheaper to produce. The manufacturing process is fast, energy-efficient, and scalable, meaning you can produce thousands of bottles in just a few hours.

For companies, it’s a win-win situation: lower costs and higher production efficiency without compromising on quality.

6. 100% Recyclable

This might be the best part: PET is fully recyclable. Once you’re done using a PET bottle, it can be collected, cleaned, and turned into new bottles, fibers, or even clothing materials.

Many countries are focusing on recycling PET to reduce plastic waste and promote a circular economy, where materials are reused instead of being discarded.

So, choosing PET helps both your brand and the environment.

How PET Bottles Are Manufactured

Here’s a simple breakdown of how PET bottles come to life:

1. Resin Production: The PET resin (in small pellet form) is made from PTA and MEG.

2. Drying: The resin is dried to remove moisture, because water can affect the quality of the final product.

3. Injection Molding: The dried resin is melted and injected into molds to form preforms (tiny bottle-like tubes).

4. Blow Molding: The preforms are heated and blown with high-pressure air inside molds to get the final bottle shape.

5. Cooling and Inspection: Bottles are cooled, checked for defects, and packed for delivery.

Every step is carefully monitored to ensure each bottle comes out strong, clear, and leak-proof, the kind of quality you can expect from a trusted PET bottle manufacturer in Pakistan.

Why Brands Prefer PET Bottles

From small startups to big beverage giants, brands love PET bottles for several reasons:

- They’re affordable and easy to transport

- They look professional and premium

- They offer flexibility in design

- They’re safe for food and beverages

- And most importantly, they’re environmentally responsible when recycled properly

For many businesses, PET isn’t just packaging; it’s a branding tool. It helps products look professional, feel premium, and perform reliably.

Real-Life Examples: Pakistani Brands That Trust PET Bottles

Still wondering if PET bottles are really worth it? Let’s bring it closer to home.

Some of the biggest (and most loved) brands in Pakistan already rely on PET bottles to keep their products safe, fresh, and easy to enjoy.

1. Coca-Cola Pakistan

Coca-Cola made headlines when it introduced bottles made from 100% recycled PET (rPET), a big step toward sustainable packaging in Pakistan.

2. Cola NEXT

Local brands are stepping up, too! Cola NEXT, a proudly Pakistani beverage company, designed PET bottles that use 8–10% less plastic than traditional packaging.

3. Shangrila Foods – Fruiti-O

When you grab a Fruiti-O juice on a hot day, you’re holding freshness sealed inside a beautifully clear PET bottle.

4. Hafiz Foods & Beverages

From Apple Max to Malta, Hafiz Foods relies on PET bottles for multiple drink lines.

Why Do Leading Brands Choose Blowplast for PET Bottle Manufacturing?

If you’re in the beverage or food industry, you already know how much the right bottle matters. At Blowplast, one of the top plastic bottle manufacturers in Pakistan, we get it, your packaging isn’t just a container; it’s your product’s first impression. That’s why our PET bottles are made with premium materials and state-of-the-art technology to keep your drinks fresh, prevent leaks, and let your product’s natural color and quality shine through.

Be it juice, edible oil, or ketchup, we create bottles that don’t just hold your product; they enhance its appeal and value. With Blowplast, you’re not simply choosing a PET bottle supplier; you’re teaming up with people who understand your brand’s needs and know how to make PET work perfectly for you.

Wrapping It Up

For every business that values presentation, performance, and sustainability, PET is the clear winner.

If you’re launching a new beverage, planning to expand your edible oil range, or looking to upgrade your existing packaging, PET offers the perfect mix of quality, durability, and sustainability. And when you choose a reliable plastic bottle supplier like Blowplast, you get expertly crafted packaging solutions.

Because in the end, packaging isn’t just about how your product looks; it’s about what it stands for. With PET plastic bottles, you’re sealing in your brand’s promise of quality, freshness, and care.

Leave a Reply